By: Kevin Skoko – Inside Sales / Technical Service Advisor.

The WDG-V is the fifth generation of the Ametek Thermox Combustion Gas Oxygen/CO/CH4 analyzer, which is known for it’s rugged design and reliable operation.

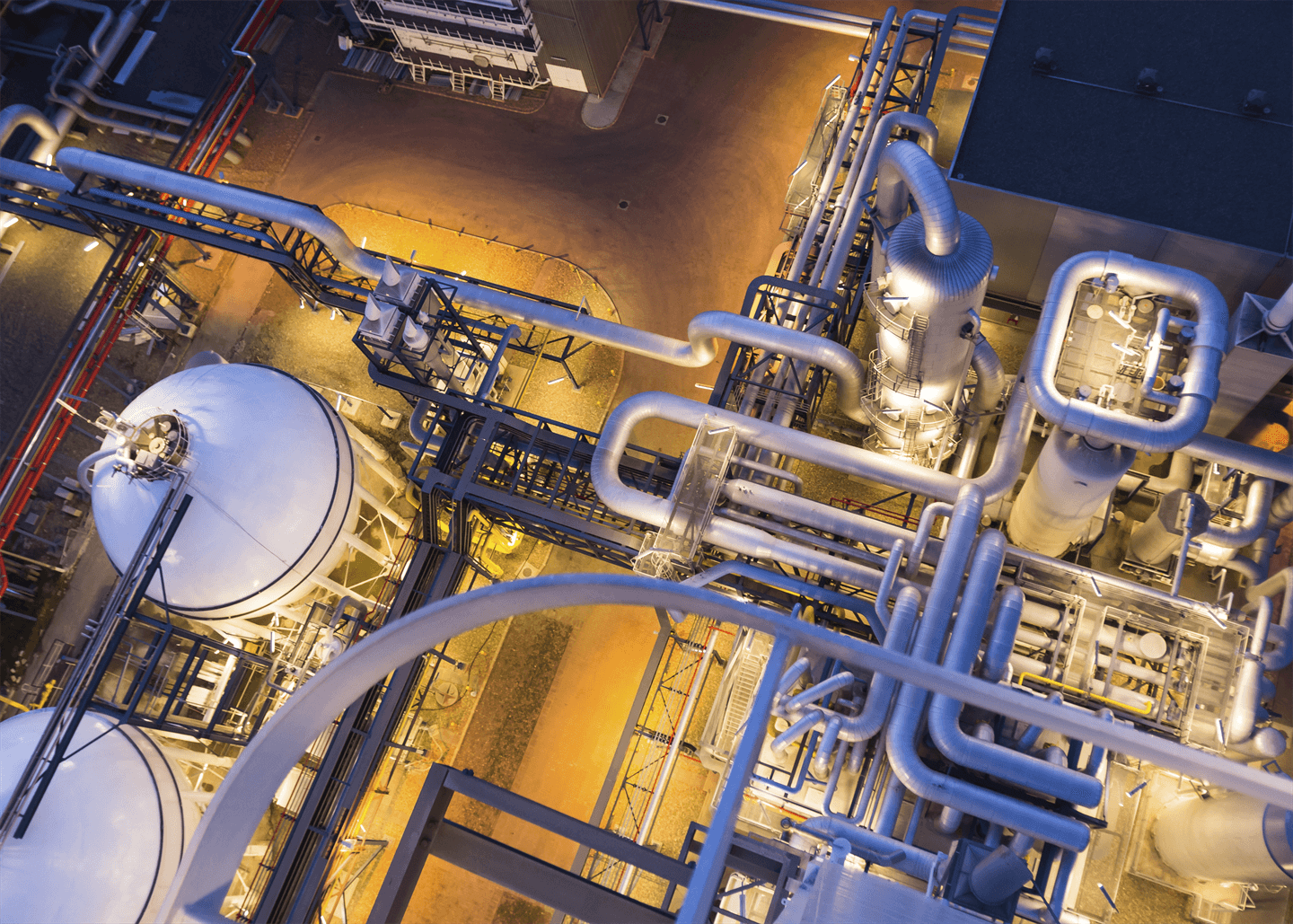

Here in Canada, where industrial plants deal with, snow, at times extreme cold, wind, and wide swings in outdoor conditions, that idea of “rugged” and “reliable” sounds very enticing. To achieve that, you need both a good analyzer, and a good installation.

In this article, we will discover together some installation tips.

Most gas analyzer installations need:

- The analyzer to remain thermally stable during process analysis, typically a requirement of the detector technology.

- The process gas to not change during the measurement cycle since you are assuming that gas inside the analyzer = the gas in the process.

- The process gas flow through the analyzer detector chamber to be constant, typically a requirement of the detector technology.

With Combustion gas, the temperatures are so extreme, this idea of a thermally constant and compositionally constant gas with an extracted sample is impossible to achieve. Nothing external can maintain the sampled gas at elevated combustion temperatures, for example 1400 °F. The sample gas is being extracted, the sample gas is being cooled, so vapour compounds in the combustion gas start condensing and solidifying. Not a big deal if what is being knocked out isn’t what you’re interested in measuring, and it’s in trace amounts, so it doesn’t shift the sample composition very much, but……. Compounds are condensing and solidifying. If you get a lot, the analyzer is plugged. That sure doesn’t sound “rugged” or “reliable”.

How much solid deposition is there? That depends on the fuel being burned in the furnace:

- Sweet natural gas there is virtually nothing that condenses out but water.

- Sour natural gas, even the low ppm level, sulfur compounds plate out, and water.

- Coal & bio-fuels: much worse. Heavy metal compounds (bismuths, asenides, etc.) as well as sulfur compounds, and water.

The Thermox analyzer design solves the sample problem of condensing combustion gases with the “close-couple extractive” design. Mount an aspirator driven fast loop right at the process wall of the furnace, and suck flue gas using a probe pipe from inside the furnace. The process gas is hot enough to flow by convection up across external detectors, and the aspirator sucks the gas back into the fast loop and out into the process. The combustion gas stays essentially entirely in the furnace except for the short time it is in the external detector loop of the Thermox analyzer.

Back to “rugged and reliable”…….

So the process gas has condensing solids, that plug up the sampling piping depending on how much it cools off, and the Thermox design uses a close couple mounting, where the idea is to leave as much of the sample system inside the furnace as possible.

Video by Ametek Process Instruments.

Tips for proper installation:

- Despite everything, the analyzer will need to be maintained and serviced, and not just during furnace shutdowns. Have some thought to the ergonomics of servicing and maintaining this analyzer:

- Is it accessible? A walkway instead of harnessing up and a man lift.

- Take into account the swing radius for opening and closing the electronics / sensor doors for the technician to accomplish his service.

- The technician has to work in front of the open sensor door when doing analyzer maintenance. There should be enough walkway room to do this without harnessing up and working under fall arrest protocols.

- A very common issue I ran across in my service work was the analyzer mounting port was welded on before the decking was installed, leaving the analyzer ½ buried in the decking, and next to impossible for accessing the electronics or sensor internals. Take into account the decking height when specifying where to weld the mounting port.

- Put a local 120V power disconnect switch adjacent to the analyzer for service work.

- Think about your fuel type and how much condensing solids there might be, and plan on keeping the process gas in the furnace as much as possible by close-couple mounting the analyzer.

- A Thermox directly mounted to the furnace wall. I’ve never ran across a plugging issue with an analyzer mounted this way. Thermal conduction is an issue as the analyzer internal wiring harness and electronics board can cook, depending on how hot the furnace wall is. Protect the analyzer as required.

- A Thermox mounted to a flanged pipe nipple. Pipe nipple 6” or less to furnace wall. Not many issues here as well. Plugging does happen in the probe pipe however, given a long enough time. Insulate the pipe nipple.

- A Thermox mounted to a flanged pipe nipple. Pipe nipple 12” or less to furnace wall. Plugging will lightly occur with this setup with sulfured fuels. Heavily insulate the pipe nipple or Aerogel insulate. Maintenance required to ram-rod the probe pipe to clear blockages approximately every 2 to 3 months, depending on how much sulfur is in the fuel.

- A Thermox mounted to a flanged pipe nipple. Pipe nipple 24” or less to furnace wall. Plugging will occur with this setup with sulfured fuels. Heavily insulate the pipe nipple or Aerogel insulate. Maintenance required to ram-rod probe pipe to clear blockages approximately monthly or greater, depending on how much sulfur is in the fuel.

- A Thermox mounted to flanged pipe nipple. Pipe nipple longer than 24”. Not recommended except for sweet natural gas fueled furnaces. Trace sulfur fuels will create plugging in the sample probe in the cold zone of the pipe nipple, even if it’s insulated. Very frequent unplugging maintenance required.

- This is Canada with Canadian winters, and almost all of the Thermox installations are outdoors. Use an insulating blanket for the sensors to assist with windchill. The analyzer runs hot and has it’s own temperature control feedback loops, however, 40 below with a 40 km/h windchill, grey blankets are a must to maintain temperature. In summer the feedback loops simply don’t work as hard with the extra insulation from the blanket if they are left on.

- Port connect a 1/3 lb check valve right on the analyzer calibration gas inlet, otherwise hot flue gas migrates out the cal gas port, and soon condensed combustion water fills the cal gas tubing run. In winter it freezes. Prevent this with a check valve.

So best practices are to mount the analyzer as close as you can to the furnace wall, and use the flue itself to keep your sample hot to prevent plugging. Use an insulating blanket to keep the analyzer thermally stable during Canadian weather, and please put some thought into the technician that has to go out and service the analyzer. Superior design that eliminates risk is far more effective than superior procedures with state of the art PPE.

A Thermox installed so it doesn’t plug, and is fairly straightforward to service for site I & E staff, will be the rugged, reliable analyzer you were looking for.

Kevin Skoko was our Thermox service technician for 15 years, and personally commissioned, started up and serviced over 200 analyzers in western Canada during Canada’s oilsands expansion of the last two decades. He is available for technical assistance on the Thermox product line by contacting your Novatech Sales person.